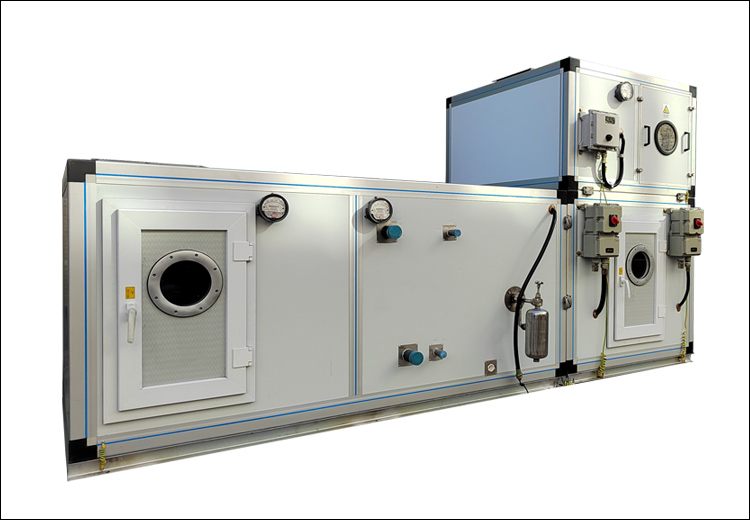

Precision Constant Temperature and Humidity Purification AC

Purification type combined air conditioning unit for pharmaceutical factory

- Product description: Purification type combined air conditioning unit for pharmaceutical factory

Since the large-scale GMP transformation of pharmaceutical manufacturers, air cleaning technology has been widely used, and more and more pharmaceutical cleaning plants have been put into use, which has greatly promoted the development of air cleaning technology. How to organically combine air cleaning technology with the GMP certification system has become a topic facing the majority of engineering and technical personnel and air-conditioning equipment manufacturers. On the basis of decades of successful practice, SMSCOLD Refrigeration has successfully developed this purification type air-conditioning unit for pharmaceutical factories. This unit has adopted comprehensive bacteria control measures to eliminate the possibility of bacterial reproduction, so that the unit fully meets the requirements of pharmaceutical factories for air cleanliness and environmental control. At the same time, this unit is also suitable for other places with cleanliness and sterility requirements.

This unit has a variety of models, specifications and configurations to fully meet customer needs.

This series of purification type air-conditioning unit is divided into fresh air unit, circulating fan unit and exhaust fan unit according to the place of use; according to the cold source, it is divided into direct expansion type and chilled water type; according to the structure, it can be divided into horizontal type, vertical type and ceiling type.

Features:

1) Use anti-corrosion and anti-bacterial materials to make the inner wall board to meet the standard anti-rust, anti-corrosion of disinfectants, and not easy to breed bacteria.

2) The electric heating adopts PTC or similar heaters that are not easy to accumulate dust, rust, and dust.

3) The wind speed through the coil tube is less than 2.5m/s, the wind speed is uniform across the section, and the stainless steel water pan.

4) The humidifier adopts steam or electrode type. It is not allowed to use wet film and other enthalpy humidification methods to ensure that the humidifier does not accumulate water after shutting down to avoid bacterial growth.

5) Adopt frequency conversion fan and frequency conversion controller for air volume adjustment.

6) Adopt a disposable filter.

7) Adopt temperature priority control scheme, and the relative humidity of the air outlet is not higher than 75%. After the shutdown, the fan is turned off with a delay to ensure that the coil is dried. Duty fan frequency conversion or two-speed operation to ensure pressure difference, and automatically restart after power failure.

8) Ultraviolet ray sterilization is used in the cooling section and the air outlet section, and an ozone generator and nano-photocatalyst can be added to the air outlet section, which can effectively kill bacteria in the air.

9) Differential pressure gauges should be installed before and after the air filters at all levels, the measuring connection is unobstructed, and the installation is tight.

For further Information, Please click to leave your message, we will contact you in the earliest time.

Categories

Latest News

Contact Us

Contact: Sunny Huang

Phone: 0086-13924653704

Tel: 0086-13924653704

Add: Baoan, Shenzhen, China