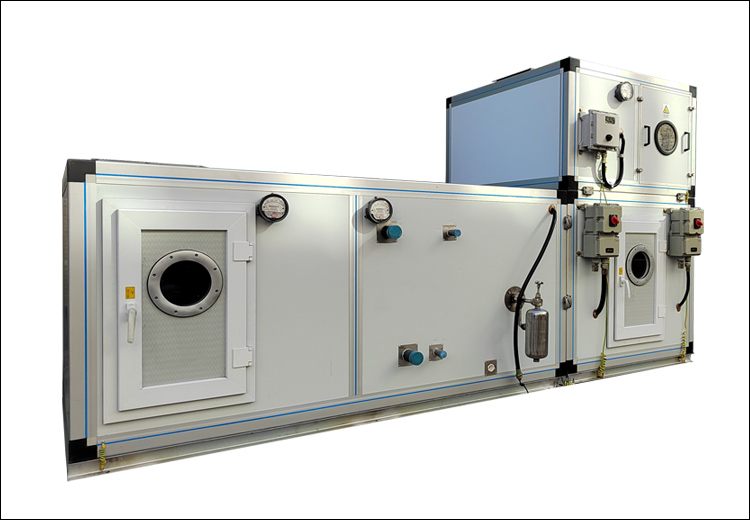

Precision Constant Temperature and Humidity Purification AC

Coating work combined air conditioning unit

- Product description: Coating work combined air conditioning unit

Coating work combined air conditioning unit

With the rapid development of the coating industry, the requirements of the coating process for environmental cleanliness, temperature and humidity are getting higher and higher. Due to the high demand for the fresh air volume during the coating process, the energy consumption will be very large. On the basis of decades of successful practice, SMSCOLD Refrigeration has developed a dedicated purification combined air-conditioning unit for the coating production line.

This unit has a variety of models, specifications and configurations to fully meet customer needs.

This series of purification type air-conditioning unit is divided into fresh air unit, circulating fan unit and exhaust fan unit according to the place of use; according to the cold source, it is divided into direct expansion type and chilled water type; according to the structure, it can be divided into horizontal type, vertical type and ceiling type.

Features:

1) The intake section of the fresh air unit adds circulating water wet film, spray, water washing and other enthalpy-reducing humidification functions. In summer, tap water is used to pre-cool and remove dust; in winter, groundwater is used to preheat, remove dust and humidify. it could so that reduce the energy consumption of air conditioning.

2) Add paint blocking board, paint mist filter, spray, natural gas combustion and other functional sections to the air inlet section of the circulating fan unit of the spraying room to eliminate paint odor in the air supply system.

3) Electric heating, electric humidification and other air conditioning methods should not be adopted for the circulating fan unit of the spraying room. The motor is placed outside the unit to prevent electrical safety accidents.

4) The electric heating and humidification of the unit should adopt stepless linear adjustment to meet the requirements of room control accuracy.

5) The humidifier adopts high-pressure spray, high-pressure micro-mist, ultrasonic, two-fluid humidification and other enthalpy-reducing humidification methods to reduce the energy consumption of the unit.

6) The fan can be adjusted with variable frequency motor and frequency converter.

7) Multi-layer aluminum primary filter is used, which can be cleaned and used repeatedly.

8) Differential pressure gauges should be installed before and after the air filters at all levels, the measurement connection is unobstructed, and the installation is tight.

For further Information, Please click to leave your message, we will contact you in the earliest time.

Categories

Latest News

Contact Us

Contact: Sunny Huang

Phone: 0086-13924653704

Tel: 0086-13924653704

Add: Baoan, Shenzhen, China