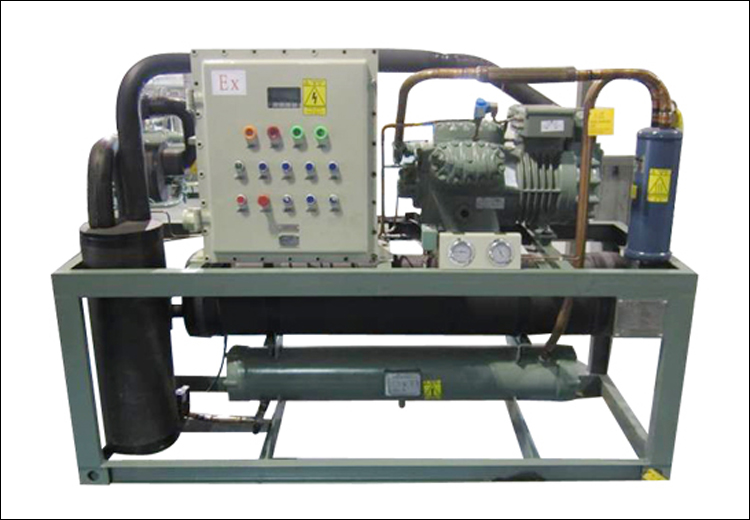

Screw Chiller

Water cooled screw chiller

- Product description: Water cooled screw chiller, water cooled water chiller

Water-cooled screw chiller

SMSCOLD water-cooled screw chillers are widely used in fields that require refrigeration such as chemical industry, extrusion equipment, aluminum alloy processing, food processing, medicine, electronics, new energy and so on. Our company provides customers with customized solutions throughout the entire process, as well as comprehensive technical support such as installation, commissioning, and trial operation.

Features:

1) Adopting high-efficiency and energy-saving compressors of internationally renowned brands (Germany BITZER, China (Taiwan) HanBell, etc.), matching high-quality condensers and evaporators, high cooling efficiency, stable performance, low noise and long service life.

2) The industrial-grade PLC centrally control the energy ratio of the compressor, and accurately controls the cooling capacity and cooling load of the unit in real time to achieve the best matching state, to ensure that the unit runs at the best efficiency and to reduce operating costs.

3) The internal integrated water cut-off low temperature high and low pressure antifreeze, lack of phase delay start, reverse phase overload, motor overheating, oil pressure difference and many other safety protection and processing functions.

4) Humanized operation interface, which can arbitrarily set the operating status of the unit and the operation environment of home appliances.

5) Capacity control can adopt four-stage (100%-75%-50%-25%), three-stage (100%-66%-33%) or stepless control system.

6) Unique built-in oil pressure system, no oil pump is needed, and the compressor maintains the best lubrication effect. The oil separator adopts double-layer filtering method, which has good oil filtering effect, and the heat converter can exert its maximum capacity.

7) High-efficiency internally threaded copper pipes enhance the heat transfer effect and are more energy-efficient and efficient.

8) Using the latest CAD/CAM design and processing technology, the CNC machining center is completed, with compact structure, small size and durability.

9) The U-shaped structure of the heat exchange tube bundle is convenient for maintenance and prevents refrigerant leakage.

For further Information, Please click to leave your message, we will contact you in the earliest time.

Categories

Latest News

Contact Us

Contact: Sunny Huang

Phone: 0086-13924653704

Tel: 0086-13924653704

Add: Baoan, Shenzhen, China