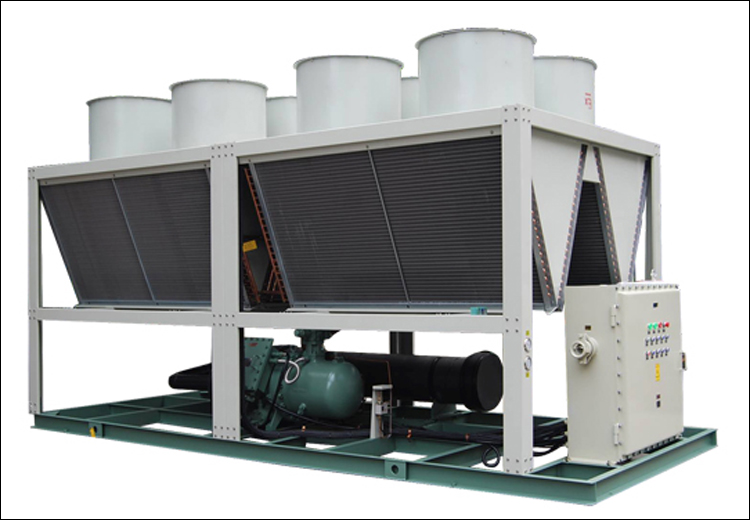

Air Cooled Chiller

Air-cooled screw chillers

- Product description: Air cooled screw water chillers, AC chiller, air cooled liquid chiller

Air Cooled Chiller, air cooled liquid chiller, in short AC chiller,

SMSCOLD air-cooled screw chillers,use high-quality international brand screw compressors, high-efficiency condensers and evaporators, and all other key components are selected internationally renowned brands. The unit has the advantages of small footprint, low noise, high energy efficiency, easy operation and long service life.

depend on the compressor equipped, it is called as air cooled scroll chiller while equipped with scroll compressor, air cooled piston chiller, etc.

Aluminum fins and copper tubes type heat exchanger. The aluminum fins are correctly spaced to guarantee the best heat exchange efficiency. The lower part of the exchanger functions as a sub-cooling circuit thus increasing the cooling capacity.

International brand compressor.

For Industrial screw chiller, we equipped with Hanbell and Bitzer compressor, to ensure the the high quality and stable performance.

For industrial scroll chiller, we use world-class brands compressor, such as Danvers, Hitachi, Panasonic, Copeland, Mitsubishi, etc.

Features of industrial air cooled water chiller.

1) A new type of high-efficiency screw rotary sub-compressor, which is 20%-30% more energy efficient than general compressors, and has obtained a number of national patents and industry international quality certifications.

2) High energy efficiency 5:6 patented asymmetric rotor tooth profile.

3) The capacity can be four-stage (100%-75%-50%-25%), three-stage 100%-66%-33%), stepless speed control.

4) The combined design of 11 bearings and A-type axial thrust balance drum greatly improves the service life of the bearings.

5) The use of high-efficiency silicon steel sheet special groove design, and equipped with internal and external omnidirectional design cooling flow, so that the compressor motor can exert the highest energy efficiency under any load.

6) The unique built-in oil pressure system can ensure the compressor in the best lubrication state without an oil pump. The oil separation adopts a double-layer filter method, which has obvious oil filtering effects and the heat exchanger can exert its maximum capacity.

7) A variety of refrigerants are available: R22, 407, 410, 134.

8) The compressor capacity ratio can be adjusted to minimize energy consumption.

For further Information, Please click to leave your message, we will contact you in the earliest time.

Categories

Latest News

Contact Us

Contact: Sunny Huang

Phone: 0086-13924653704

Tel: 0086-13924653704

Add: Baoan, Shenzhen, China